Menu

Menu

Auckland’s wastewater network operates 24 hours a day, 365 days a year. It never shuts down.

So when a newly installed wastewater pipework in South Auckland’s Park Estate needed to be connected into the existing operational Watercare network, time was of the essence.

Connecting to an existing live wastewater line in the ground meant the contractor Dempsey Wood and Northwater needed to operate within a limited time window and in a constrained space with other services present.

Richard Morron, Business Development Manager - Water from Hynds Water, worked with the consultant engineer and Watercare on the project.

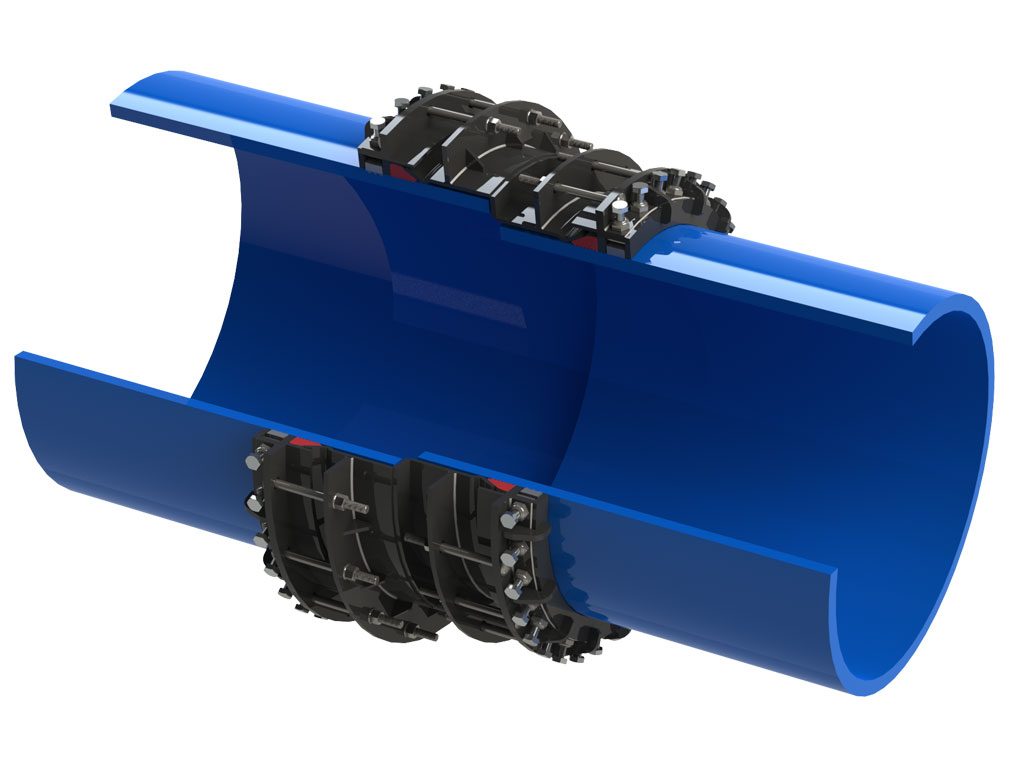

“After reviewing the requirements of the job we suggested Nova Siria Multigrip couplers as a solution,” says Richard.

“The reasoning for this is that Nova Siria Multigrips are a fully restrained mechanical coupler that can be installed in restricted access areas simply using spanners and a torque wrench. They can also be used in wet conditions with no issues.”

This approach eliminated the need for electrofusion or butt welding of the PE pipe which can be weather dependent and require electrical leads and a power source. Also, using the mechanical Nova Siria couplers enabled the contractor to work on multiple areas at once rather than waiting for EF or butt welds to cool down.

Richard provided hands-on training ahead of the work commencing so that all parties were familiar with the product and knew recommended practice for installation.

“It is possible to divert flows for a limited amount of time with sucker trucks whilst work is carried out, only during off-peak network demand."

"The asset owner had to have this new line connected in and back up and running before peak demand, later that day,” explained Richard.

“When there is a shut down like this the job needs to be done right first time.”

The job was carried out within the allotted timeframe, the main transmission line was recommissioned and recommenced operation with no issues.

Navigating the Challenge:

Along with an ageing water network, Wellington Water have the ever-present risk of seismic activity to consider. Mitigating the risk of water disruption is front of mind as Wellington Water develop and roll out a sustainable strategic plan, including seismic resilient pipelines.

Wellington Water resolved to improve the flexibility of a critical DN900 bulk water steel main situated along the Esplanade in Petone. The pipeline connections on either side of a valve chamber presented an increased risk of failure in the aftermath of an earthquake event.

Forging a Resilient Path

United under the Hynds Group - Hynds Pipes, Hynds Water, and Hygrade Water collaborated seamlessly with Wellington Water to orchestrate a dual-pronged solution: Seismic Resilient Ductile Iron pipe (SRDiP) in conjunction with Flex-Tend® Flexible Expansion Joint connections.

The Wellington Water Bulk Water Team subsequently installed two substantial Flex-Tend® joints either side of the valve chamber, each weighing 4.5 tonnes. The operation was supported by a custom-built cradle to help steady the devices as they were positioned in place.

In an area considered at higher risk of liquefaction along the shoreline, the ripple effect of this intervention to the security of the city water supply is significant.