Menu

Menu

Navigating the Challenge:

Along with an ageing water network, Wellington Water have the ever-present risk of seismic activity to consider. Mitigating the risk of water disruption is front of mind as Wellington Water develop and roll out a sustainable strategic plan, including seismic resilient pipelines.

Wellington Water resolved to improve the flexibility of a critical DN900 bulk water steel main situated along the Esplanade in Petone. The pipeline connections on either side of a valve chamber presented an increased risk of failure in the aftermath of an earthquake event.

Forging a Resilient Path

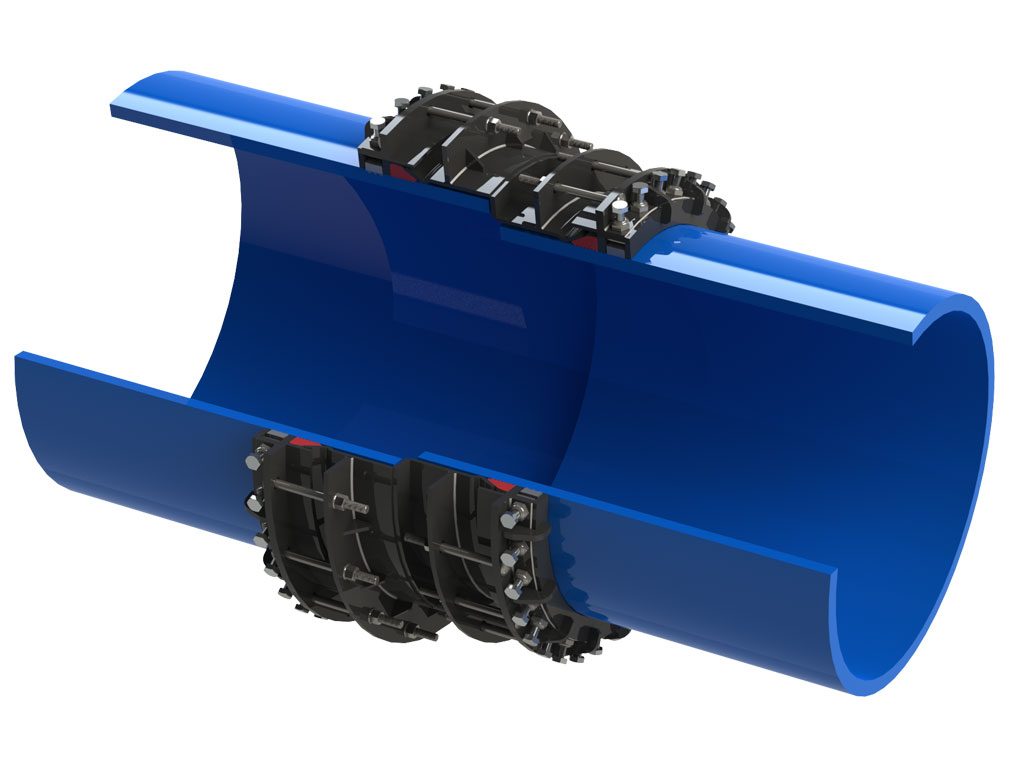

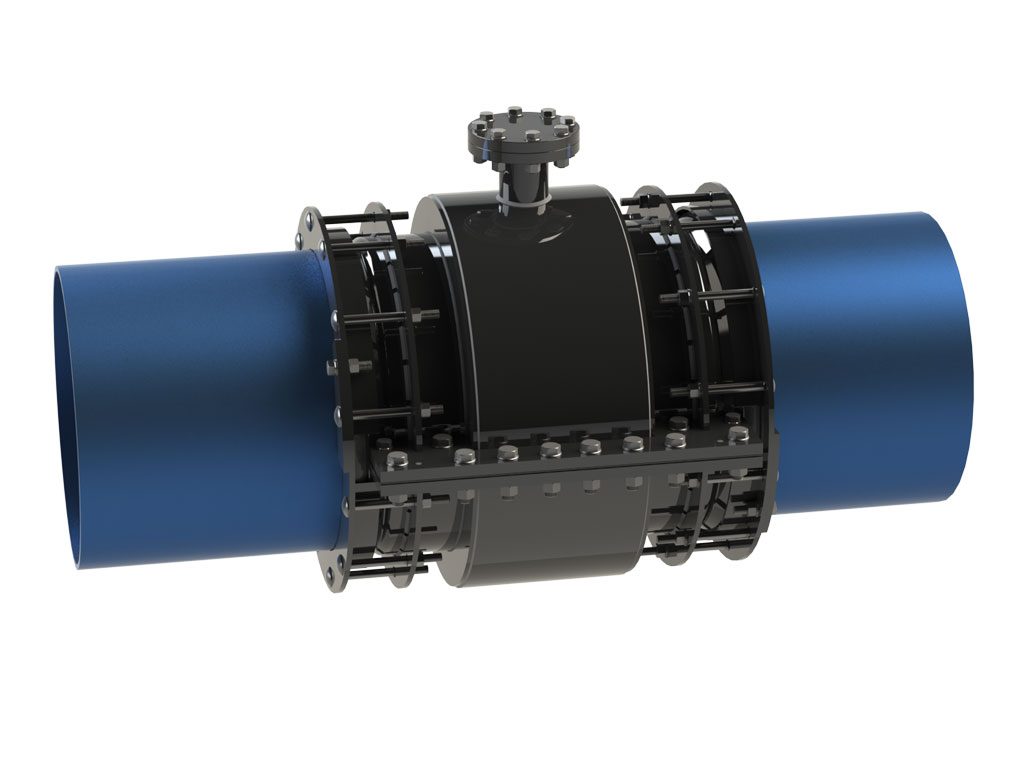

United under the Hynds Group - Hynds Pipes, Hynds Water, and Hygrade Water collaborated seamlessly with Wellington Water to orchestrate a dual-pronged solution: Seismic Resilient Ductile Iron pipe (SRDiP) in conjunction with Flex-Tend® Flexible Expansion Joint connections.

The Wellington Water Bulk Water Team subsequently installed two substantial Flex-Tend® joints either side of the valve chamber, each weighing 4.5 tonnes. The operation was supported by a custom-built cradle to help steady the devices as they were positioned in place.

In an area considered at higher risk of liquefaction along the shoreline, the ripple effect of this intervention to the security of the city water supply is significant.

The New Wellington Children’s Hospital: Pioneering Seismic Resilience and Engineering Excellence:

Situated with an Importance Level 3 classification, the new Wellington Children's Hospital stands as a testament to cutting-edge seismic resilience. With a robust rating capable of enduring a once-in-a-2,500-year seismic event, the hospital not only safeguards patients and staff but also ensures swift recovery and operational continuity after a significant earthquake.

At its core lies a ground-breaking foundation: Triple Pendulum Base Isolators, meticulously designed and manufactured in San Francisco. These specially engineered isolators grant the building the ability to sway up to an impressive 1.5 meters in two directions. This ingenious design pre-empts potential risks to critical sanitary sewer and stormwater infrastructure, strategically mitigating large displacements during seismic events across the base isolation plane.

Aurecon Hydraulic Building Services Engineers collaborated with the Hynds Group to orchestrate the specific engineering design of the Hynds proprietary Flex-Tend® Flexible Expansion Joint. In synergy with the main contractor's BIM team, each connection was developed in Revit, ensuring seamless integration within the digital realm, before submitting as shop drawings for procurement with EBAA USA.

Senior Project Engineer Ray Yee commented that: "From concept, construction and hand-over to Te Whatu Ora late 2022, Hynds have been exemplary in the development of this critical component for this world-class medical facility. Aurecon New Zealand highly recommend Hynds for their commitment, innovation, and expertise in seismic engineering design."

When the treated water pipelines from the Waingake Water Treatment Plant were damaged by cyclone Gabrielle, Gisborne’s drinking water was compromised.

The Gisborne District Council had multiple challenges within the water supply infrastructure, but the immediate focus was on repairs to get limited treated water to where it was needed.

The existing 525mm O/D concrete lined steel pipeline was attached to the TWLPB4 bridge which suffered substantial damage to both the bridge and abutment which also supported a 11kVa powerline. There were a further 7 bridges that failed along with 9 major breaks in the pipeline. Access to the pipeline was challenging.

The Solution

Fulton Hogan installed 500mm SDR17 HDPE to the affected areas but needed to tie in to the existing 525 concrete lined steel pipe.

Hynds Water were able to provide 2 x DN 500 Novia Siria Multigrip couplers and liners to complete the urgent repair. The couplers have a wide tolerance that allowed two different pipe materials with dimensions to be connected. They are a restraint fitting which ensures the HDPE pipe is securely anchored to the fitting.

Featherston’s water network is supplied by a transmission pipe from Waiohine water treatment plant. Where the pipeline crosses the Tauherenikau river, the section of pipe that is exposed is approximately 23m long. Of the exposed section, around 15m of pipe is concrete encased and the remaining 8m is made up of steel pipe. A break in the coupler on the exposed section was identified on the 3rd December 2021. The leak only became visible when the river level was low. The area of the pipe around the leak suggests this may have been leaking undetected for some time and not visible due to high river levels.

A contingency plan for this scenario has been refined and a repair plan had to be created. The fix identified is in two phases: the first to stabilise the existing pipe to ensure sustainable water supply in shot term, with a second to replace the pipe with fully sustainable system that will last, many years.

Article by: Brent Merritt – Business Development Manager – Hynds Water

Duo-Fit repair couplers are manufactured and supplied in two pieces with heavy duty seals, allowing for a “wrap around” repair and no pipe shut down.

For help with installation see our Repair Guide

In 2018, Cyclone Gita caused havoc across the lower North Island. New Plymouth was hit particularly hard, causing widespread power outages, felled trees and landslips and major pipe damage to one of the potable water supplies.

During the cyclone one of those trees fell directly onto a major watermain pipe that feed to 10,000 homes which left them without water for three days, causing the residents to go directly on a boil water notice. Schools and businesses had to close which caused an economic impact of $4.5 million dollars.

NPDC saw the need to upgrade and invest in pipes and fittings to cater for all of their reticulation critical spares. Hynds Water worked directly with the project manager and provided solutions for all of the different pipe sizes, all types of repair solutions catering for all pressures across the three waters network. Some of our major brands could offer custom built pipe fitting solutions for pipes that are not even made to this day!

Now NPDC have a brand-new purpose-built facility that stores an extensive supply of fittings and other infrastructure spares including critical pipe! As well as a modern inventory system with scan codes, electronic access to instructions and diagrams and life reminders for perishable items held in the store.

Article by: Brent Merritt – Business Development Manager – Hynds Water

28th March 2022

31st March 2022

8th April 2022

11th April 2022

18th April 2022

28th April 2022

Our customer had to complete a cut in of a new valve assembly on an existing wastewater pressure main in a confided space environment, all inside a limited time window.

Three different pipe materials Concrete Lined Steel, Ductile Iron and Polyethylene had to be joined to, all with varying OD’s.

The contractor found that Synoflex flange adaptors offered the best solution for this job. The wide outside diameter tolerance with good angular deflection and a restrained grip ring meant that this job could be done right first time and within time.

Additionally utilising Synoflex eliminated an EF coupler and a PE reducer from the original design saving additional time and costs.

Article by: Richard Morron – Business Development Manager – Hynds Water • Sales Northern

Restraint multi-range connection for all kinds of pipes. The Hawle Synoflex socket system is suitable for the restraint connection of all kinds of pipes generally used in the water industries. By means of the patented Hawle Synoflex you can establish corrosion-protected and high-quality connections of the most various kinds of pipes (DI, CI, PE, PVC, steel).

Available in sizes DN50 - 300.

For help with installation see our Repair Guide

See our Hynds Water Catalogue.

Hynds Water have been working with the Watercare project delivery team and Fulton Hogan on the East Coast Bays Booster Pump Station Project. We were involved with this contract from the early stages allowing us to provide advice, solutions and alternative options. All of this has enabled this contract to go ahead based on tight timelines.

These photos show the latest stage of play with some of the product we supplied to this site.

Article by: Richard Morron – Business Development Manager – Hynds Water • Sales Northern

Jobs don’t always go together as planned, sometimes it’s the design, sometimes the goal posts get shifted mid-game. These photos are from a Watermain install in South Auckland that required a bit of the Hynds Water “we’ll make that problem go away for you” attitude. When this happens it’s always great to be able to call on the many years of experience we have in the Hynds Water team and in the wider Hynds business. Our Hawle Valves, Gillies DI and Georg Fischer product all went together to make a solution that worked for this project.

Article by: Richard Morron – Business Development Manager – Hynds Water • Sales Northern

Hawle pioneered the resilient seated sluice valve.

Download Technical Guide - DN50 – DN200

Download Technical Guide - DN250 – DN600

See our Hynds Water Catalogue.

Hynds Water stock a comprehensive range of NZ made Gillies Ductile Iron Fittings including flanged, socket, and spigot ends.

We also offer the Hawle-Vario. A flanged telescopic fitting with ball and socket joint, allowing variable length and up to 10 degress deflection.

See our Hynds Water Catalogue.

Hynds Water were selected as supply partner for this drill shot under State Highway 1 north of Auckland, product included PE pipe, Ductile Iron Fittings Valves and Electrofusion couplers.

Teamwork between all stakeholders on this contract was critical as there was no room for error. Hynds Water worked with all the key parties and contributed by providing specialist advice and onsite technical support. We ensured the contractors had the right products to meet Watercare’s standards and the job specification.

This is the first of two shots which will provide water and wastewater trunk mains to a new sub division.

Article by: Richard Morron – Business Development Manager – Hynds Water • Sales Northern

The Hynds Water Team worked closely with one of our valued customers providing water products, advice, service, and timely supply for several Watermain sub-division installations in West Auckland. Getting it right first time including supplying world leading quality brands like Hawle valves and Gillies Ductile Iron Fitting, which ensures the installer and asset owner a robust and enduring asset life. Our customer also benefits with peace of mind knowing that the job would only have to be done once.

Article by: Richard Morron – Business Development Manager – Hynds Water • Sales Northern