Menu

Menu

Navigating the Challenge:

Along with an ageing water network, Wellington Water have the ever-present risk of seismic activity to consider. Mitigating the risk of water disruption is front of mind as Wellington Water develop and roll out a sustainable strategic plan, including seismic resilient pipelines.

Wellington Water resolved to improve the flexibility of a critical DN900 bulk water steel main situated along the Esplanade in Petone. The pipeline connections on either side of a valve chamber presented an increased risk of failure in the aftermath of an earthquake event.

Forging a Resilient Path

United under the Hynds Group - Hynds Pipes, Hynds Water, and Hygrade Water collaborated seamlessly with Wellington Water to orchestrate a dual-pronged solution: Seismic Resilient Ductile Iron pipe (SRDiP) in conjunction with Flex-Tend® Flexible Expansion Joint connections.

The Wellington Water Bulk Water Team subsequently installed two substantial Flex-Tend® joints either side of the valve chamber, each weighing 4.5 tonnes. The operation was supported by a custom-built cradle to help steady the devices as they were positioned in place.

In an area considered at higher risk of liquefaction along the shoreline, the ripple effect of this intervention to the security of the city water supply is significant.

The New Wellington Children’s Hospital: Pioneering Seismic Resilience and Engineering Excellence:

Situated with an Importance Level 3 classification, the new Wellington Children's Hospital stands as a testament to cutting-edge seismic resilience. With a robust rating capable of enduring a once-in-a-2,500-year seismic event, the hospital not only safeguards patients and staff but also ensures swift recovery and operational continuity after a significant earthquake.

At its core lies a ground-breaking foundation: Triple Pendulum Base Isolators, meticulously designed and manufactured in San Francisco. These specially engineered isolators grant the building the ability to sway up to an impressive 1.5 meters in two directions. This ingenious design pre-empts potential risks to critical sanitary sewer and stormwater infrastructure, strategically mitigating large displacements during seismic events across the base isolation plane.

Aurecon Hydraulic Building Services Engineers collaborated with the Hynds Group to orchestrate the specific engineering design of the Hynds proprietary Flex-Tend® Flexible Expansion Joint. In synergy with the main contractor's BIM team, each connection was developed in Revit, ensuring seamless integration within the digital realm, before submitting as shop drawings for procurement with EBAA USA.

Senior Project Engineer Ray Yee commented that: "From concept, construction and hand-over to Te Whatu Ora late 2022, Hynds have been exemplary in the development of this critical component for this world-class medical facility. Aurecon New Zealand highly recommend Hynds for their commitment, innovation, and expertise in seismic engineering design."

When the treated water pipelines from the Waingake Water Treatment Plant were damaged by cyclone Gabrielle, Gisborne’s drinking water was compromised.

The Gisborne District Council had multiple challenges within the water supply infrastructure, but the immediate focus was on repairs to get limited treated water to where it was needed.

The existing 525mm O/D concrete lined steel pipeline was attached to the TWLPB4 bridge which suffered substantial damage to both the bridge and abutment which also supported a 11kVa powerline. There were a further 7 bridges that failed along with 9 major breaks in the pipeline. Access to the pipeline was challenging.

The Solution

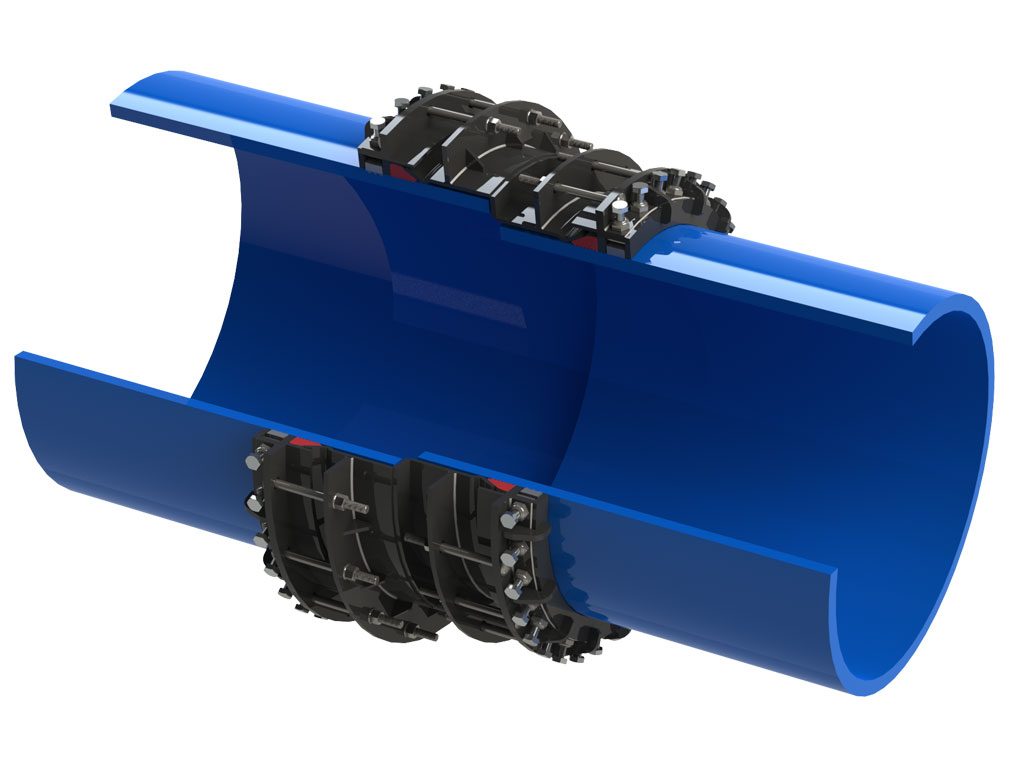

Fulton Hogan installed 500mm SDR17 HDPE to the affected areas but needed to tie in to the existing 525 concrete lined steel pipe.

Hynds Water were able to provide 2 x DN 500 Novia Siria Multigrip couplers and liners to complete the urgent repair. The couplers have a wide tolerance that allowed two different pipe materials with dimensions to be connected. They are a restraint fitting which ensures the HDPE pipe is securely anchored to the fitting.